How To Install Insulation Under Mobile Home

If you insulate under a mobile dwelling you can save money. Over the concluding 3 decades, the National Renewable Energy Laboratory (NREL) has partnered with the US Department of Free energy to test diverse methods of free energy efficiency for old and new manufactured homes. Adding better insulation to the walls reduced heat loss past 13%. Coming in a close 2d was adding better insulation to the underbelly, nether the sub-floor but above the belly wrap. Information technology reduced rut loss past 11%. Installing storm windows also decreased heat-loss by 11%.

Every bit with most everything involving mobile homes, in that location is confusion surrounding the mobile dwelling underbelly or crawlspace under the abode. One reason for the confusion is the numerous names used to describe the aforementioned thing. Mobile habitation belly board is also called a mobile habitation belly wrap, underbelly, bottom wrap, bottom board, belly, and belly bulwark. Regardless of the word you lot utilise, it needs to exist well-insulated.

In this article, we cover the best materials and method to insulate nether a mobile home. Nosotros besides share how one couple insulated and repaired their ain mobile home underbelly using foam board.

Blowing Insulation into the Belly of your Mobile Abode

Equally nosotros shared in our complete mobile dwelling insulation guide, blowing insulation into the belly and the ceiling of a mobile home is the near recommended method to insulate nether a mobile domicile.

Even so, this method of insulating a mobile home underbelly requires specialized equipment and advanced knowledge of a mobile home'south construction. Therefore, blowing insulation can be expensive. Fortunately, in that location are many state and local government programs that may help mobile dwelling owners to add insulation via energy grants and depression-interest loans.

Depending on your location you may authorize for a program or financing assistance to get your mobile dwelling insulated better, specially if it was built before 1976.

Tiptop Materials to Insulate Under a Mobile Home

While blown insulation is the favorite method of insulating a mobile home underbelly it is also expensive because you have to hire it out. Using cream, fiberglass, or Rockwool panels gives the homeowner the opportunity to DIY which is commonly always a cheaper selection.

Spray Cream

Spray foam is most recommended for already enclosed areas such as the walls or ceiling/roofing of a mobile home. It'southward fairly expensive because you have to accept special equipment.

Spray insulation tin be fabricated of a diversity of materials. Near common is cellulose (newspaper), foam, and fiberglass. Learn more than about spray foam here and here.

Advantages of Cream Insulation

Foam insulation has many advantages. Here are just a few:

- easy to cutting with a utility knife, hand saw, or table saw

- lightweight and easy to carry

- flexible enough to easily maneuver into tight spaces – DIY friendly

- doesn't promote mold growth

- water resistant

- long-lasting – won't decay

- insecticide is used on most foam making

Since foam board can also act as both an insulator and a vapor barrier for your mobile habitation it's ideal to install under your flooring.

Disadvantages of Foam

Fire is probably the biggest disadvantage of foam board insulation and meeting your local burn down protection codes may be bothersome. Foam is fairly hard to ignite, but one time it catches information technology emits a dumbo smoke and toxic gases. Nonetheless, some manufacturers spray the foam with fire retardant. You'll want to research your local codes.

Iii Common Types of Rigid Cream Insulation

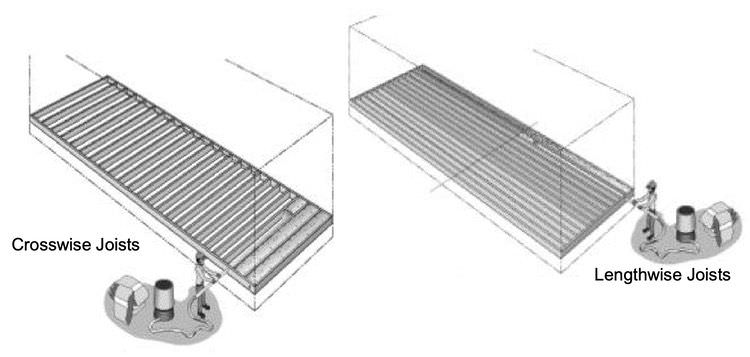

Prototype Source

The three nearly common types of foam lath are made of polystyrene, polyisocyanurate, and polyurethane. All are petroleum-based products.

Rigid foam can exist used in walls, roofs, and foundations, for retrofits or new structure. Most varieties of foam have a higher R-value per inch than fiberglass, cotton fiber, or cellulose. (Green Building Advisor)

Here are the three main types of rigid cream insulation:

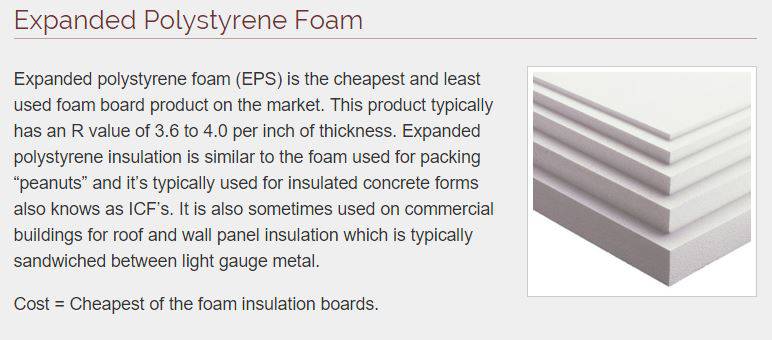

Molded Expanded polystyrene (EPS or MEPS)

(Prototype source)

Expanded polystyrene is the most common type of foam insulation and the most affordable.

It is made from the same closed jail cell cream beads that your coffee cups and shipping peanuts are made from. It is molded, or extruded, into big sheets that can be used in roofing, flooring, siding, and other construction needs.

The R-value of EPS sheets depends on the density, with a unmarried sheet of foam ranging from 3.half-dozen to 4.two per inch.

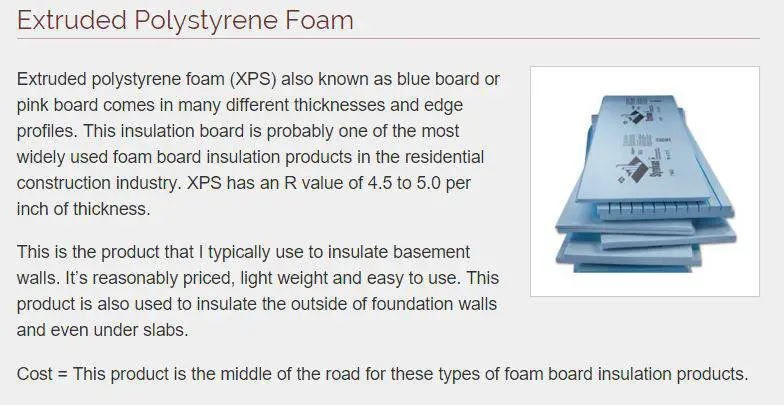

Extruded polystyrene (XPS)

(Image source)

Extruded polystyrene is very similar to expanded polystyrene but information technology uses pellets instead of beads, making it smoother and denser. Information technology too has meliorate water resistance. Yous'll recognize this production by its colors – it comes in blue, pinkish, and green depending on the manufacturer.

You'll pay more for extruded polystyrene but you'll go amend free energy efficiency. The R-value of extruded polystyrene is effectually 5 per inch.

Extruded polystyrene is ideal for basements and slabs and makes an ideal pick for insulating under a mobile habitation if the added cost isn't an issue.

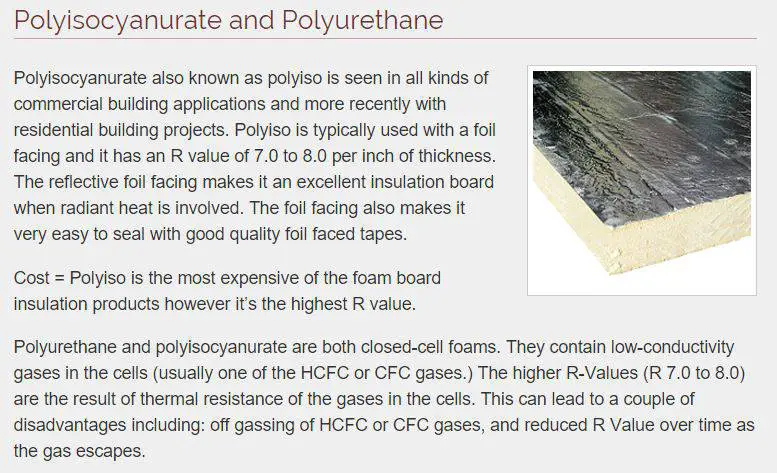

Polyisocyanurate (ISO) and Polyurethane

(Image source)

Polyurethane and Polyisocyanurate have advantages and disadvantages.

They have college R-Value per foursquare inch but they are as well the well-nigh expensive of the three types of rigid foam.

Foil-faced polyisocyanurate is more resistant to ignition than unprotected XPS or EPS. For this reason, some (but not all) building inspectors let foil-faced polyisocyanurate to be left exposed on crawlspace walls or in attics without requiring a layer of drywall every bit a thermal barrier.(Source)

An reward of polyurethane is the foil that covers the sides. The foil tin can human activity every bit a vapor barrier and is used most often in roofing and foundations.

Laurel and Bryan's 'Death Zone' of Cold Air

The first year in a new home, specially an older mobile home, is ever a learning experience. That was certainly true for Laurel and Bryan Adams when they moved into a 1974 Olympic unmarried wide mobile habitation.

The couple'southward new vintage mobile home had served Laurel's aunt very well until she passed last year at the age of 93. While the mobile abode'southward decor may not have made it to the cover of Dwelling and Garden, auntie had lovingly updated it over the years. She had heroically painted the walls herself with a three-inch paintbrush in brilliant yellow and aqua.

During their first winter in the domicile, they learned how much their utilities price and where all the cold spots were located in the dwelling. Needless to say, their 1972 mobile abode had a few common cold spots and their heating costs were as well high for such a minor home. The following Spring they began researching how to best insulate their dwelling.

Laurel and Bryan decided to solve their problem energy loss using foam board. They were kind plenty to share the details of their projection with us, complete with hand-drawn images. How cool is that?

It was a sound, affordable home that had loads of potential!

The Adam's vintage mobile dwelling house sits in Edmonton, Alberta, and since older mobile homes are notoriously under insulated, they experienced wild temperature fluctuations during their first wintertime.

How to Insulate Under a Mobile Home with Cream

Once Bound arrived, the couple set out to observe a way to increment the dwelling's energy efficiency, specially in the 'expiry zone', equally Laurel playfully called information technology. The death zone was an area two to 3 feet above the floor that remained much colder than the remainder of the habitation.

Materials Used:

- 4′ 10 8′ Cream Insulation Lath

- Table saw and hand saw

- 3″ screws with 1″ washers

- Screwdriver (electric)

The Adam's were able to buy their four′ x viii′ insulation foam board from the manufacturers directly. That saved them nigh half off the retail price. It pays to cut out the middleman whenever possible!

Insulating Nether a Mobile Habitation with 2″ Cream Board

Related: 8 Energy Efficiency Ideas for Your Manufactured Home

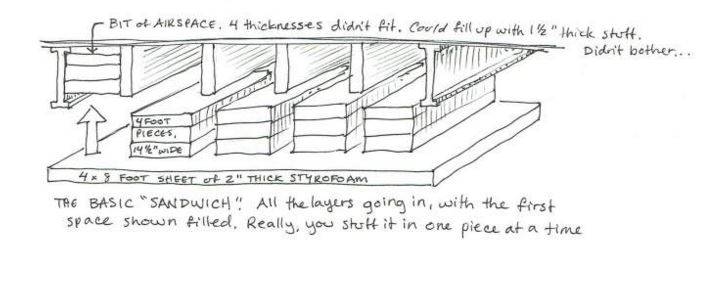

The mobile domicile'due south floor joists are on 16″ centers, which means the wood floor joists are placed sixteen″ apart from each joist'southward heart point. Since the joists themselves are roughly ane.5″ wide the department betwixt each joist was approximately 14.v″ wide.

Bryan bought 2″ thick Styrofoam insulation board and used a table saw to cutting the boards 14.5″ then that the foam was easy to push between the joists and stay put (there are iv″ cream boards available but the two″ is easier to handle).

Bryan concluded that layering 4 boards together to create an 8″ total thickness of insulating cream would work best for their surface area'south average winter temperatures.

Each stack was made of iii fourteen.five″ broad by two″ thick foam boards. The 4th foam lath was left full-size (four′ x 8′) and attached to the lesser of the wood joists. This holds the three boards above it in place and creates a total of 8″ of insulation under the unabridged mobile home.

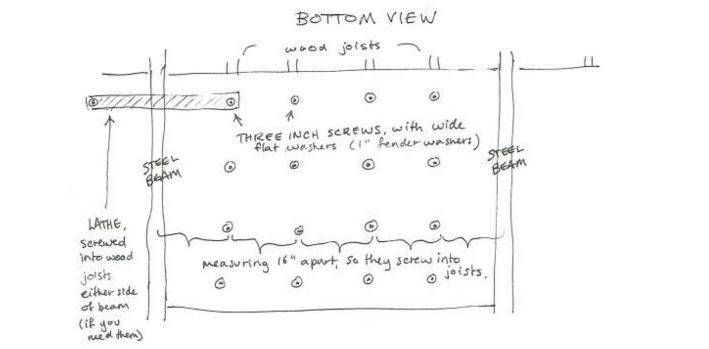

To secure the full-size sheet to the bottom of the domicile Bryan used 3″ screws with a 1″ wide fender washer. Since the habitation was congenital on 2 steel beams at an eight′ interval he used the lip of the steel beams to act as a shelf for the ends of the cream board. The forest joists are a bit shorter than the steel beams so this method worked well.

The drawing below shows it better than I can explain:

Laurel also drew a schematic of the spiral placement. She explained that had Bryan not been able to spiral into the bottom of the wood joists that he could take used a couple of different options to secure the cream. A sparse wooden lathe could have been used as a bridge to hold the foam into place.

The results of the couple's DIY insulation projection has been a great success! Laurel states that the 'dead zone' is long gone and since the foam has insulated the duct-work nether the dwelling house the forced air oestrus is reaching the cease rooms better.

Using Fiberglass to Insulate Nether a Mobile Abode

Fiberglass is the almost common insulating material. It is made of very fine strands of glass formed in rolls and loose fill batts that are installed betwixt beams, joists, and studs.

Since it is made of glass it is an excellent insulator that is affordable, non-flammable, and water resistant. The downside is that it is fairly dangerous to handle. Yous'll definitely want to use protection when working with fiberglass.

Depending on density you'll get R-value ratings ranging from R-2.9 to R-iii.viii per inch.

This is a great video that follow the whole project of removing and installing insulation under your mobile home:

Using Roxul Rock Wool to Insulate Under a Mobile Home

One proficient recommended Roxul Rockwool for a few reasons. The following benefits are from the Rockwool website:

- Non-flammable stone wool insulation with a melting point of approximately 1177°C (2150°F)

- Fire-resistant due to its loftier melting temperature

- Water and moisture resistant; does not absorb moisture to maintain insulating value

- Chemically inert

- Does non rot or promote the growth of mildew, fungi or leaner

- Chlorofluorocarbon- and HCFC- free product and process

- Made from natural and recycled materials

- ROCKWOOL® tin can contribute to earning LEED® points

Rockwool is a rigid mineral wool insulation sheathing board that is not-combustible, water-repellent, fire-resistant and sound absorbent

Dissimilar Opinions Most Insulations

Some experts may frown on the 4.5″ left over from each 48″ wide lath after getting iii cuts. That seems kind of silly of a reason to not like a project as the cream can exist used on a multitude of other things. You may even be able to get ii or iii different areas of your domicile insulated using the 'waste.'

In the construction globe yous take the wrong mode and the actually wrong manner. Everyone has an their opinion and everyone else is wrong. Ask iii different construction exerts the same question and I guarantee you volition get 3 different answers.

Related: Useful Mobile Home Repair Manuals

Installing a Ground Moisture Bulwark

It is recommended that all mobile and manufactured homes have a ground moisture bulwark. A bulwark is usually just a polyethylene plastic sheeting placed directly on the footing and secured under the domicile to human action equally another shield between earth and dwelling house. it should extend 6″ past your mobile home skirting.

The ground barrier combined with a vapor barrier (whether via a carve up belly wrap or cream installation) volition protect your mobile domicile from moisture. Information technology tin can likewise deter animals from going under your home and help you locate leaks and water problems equally the h2o volition sit on top of the plastic instead of soaking into the ground.

Cheque your Local Codes Earlier All DIY Projects

Inspections are a necessary evil in the construction world, regardless of what kind of DIY project you do. Every location, whether in Canada or America, has building codes that must exist met for all update and remodeling projects. The location of your home will impact the codes that yous will need to run into. Homes in Canada face up different issues than homes in Florida and then be certain to inquiry your local codes.

Summary for Insulating Under a Mobile Abode

Repairing and insulating under a mobile home (or the mobile home belly) isn't the most exciting remodeling project just it tin make a huge difference in your energy bills and your comfort.

Unfortunately, almost mobile homeowners have no idea how important the abdomen of their mobile habitation is to the overall condition of their home.

If your home is losing oestrus or seems harder to keep heated or cooled you may want to consider insulating under your flooring as the beginning step in updating your dwelling.

Insulating your mobile home with foam is proven to be effective. The foam is easy to use and adequately affordable for its high R-value and free energy conservation properties.

Laurel states that she doesn't remember insulating the walls would take made nearly every bit much of a divergence as the underfloor insulation has and she would know best, it hitting -4 Fahrenheit concluding calendar week and their abode stayed warm and the death zone is long gone.

A HUGE thank you to Laurel and Bryan Adams for sharing their project and pedagogy us how to insulate and repair a mobile home underbelly. and to Laurel for the awesome drawings!

Acquire more near a mobile home belly board and underbelly hither.

Give thanks you then much for reading Mobile Domicile Living!

Source: https://mobilehomeliving.org/insulating-under-a-mobile-home-with-foam-board/

Posted by: gordonnothad86.blogspot.com

0 Response to "How To Install Insulation Under Mobile Home"

Post a Comment